The Most Overlooked Component of Modern Engineering – A Slip Ring

Modern engineering is a process of many steps that finally gets us a final product that solves a problem, eases the way we do things, and helps us be more efficient and do things faster.

With so many components and aspects of modern engineering, one of the most overlooked components in modern engineering is definitely a slip ring.

Not many even know what a slip ring is, and if you’re one of the people, you’re in the right place.

Down below, you’ll learn everything about slip rings, how they are made, how they function, and what their purpose is, but even where you can find a slip ring – so keep on reading!

What is a Slip Ring and What is its Purpose?

A slip ring is a small device that attaches to a stationary part of a device and it’s used everywhere where there is both a stationary and a rotary part of a device.

Therefore, slip rings can be found in so many devices, equipment, machines, hardware, and more.

Its main purpose is the ability to solve the wire winding problems around the joints where the stationary part meets the rotary part of a device. Wire winding is a serious problem that could lead to error and the downtime of the machine as wires hanging around the joints are never a good combination.

Slip rings eliminate hanging wires and provide a more secure contact in the most necessary places.

However, with such a convenient build of slip rings, they provide way many more benefits which makes them highly versatile. Therefore, slip rings can be found in so many devices and machines across so many industries.

Combined with various types and its variations, slip rings fulfill an important purpose.

How Slip Rings Work and Function?

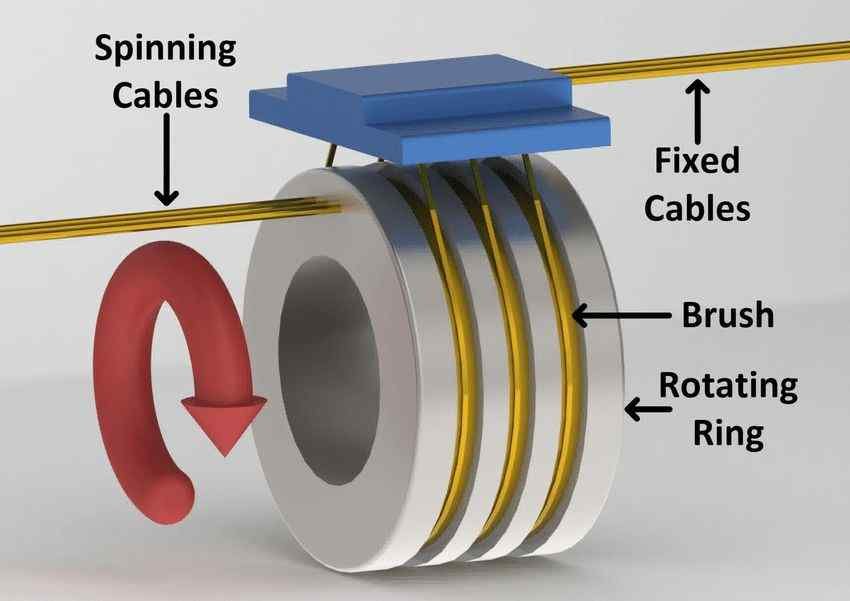

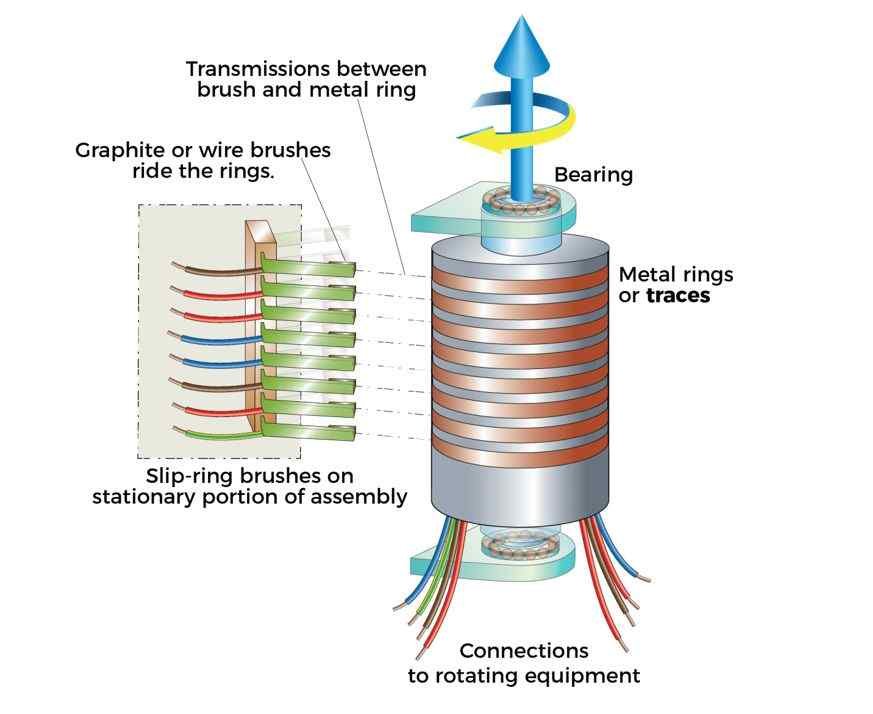

Slip rings are built in a very simple way and their design didn’t change much in decades. Two of the most important components are the ring and the brushes.

The ring is the outer casing while brushes (or wipers) are placed inside of the ring. As the rotation happens, brushes slide across the ring, making a secure contact which then can transfer electrical signal, power, and data between a stationary and a rotary part of a device.

However, keep in mind that in some situations, the outer part of the ring can rotate while brushes remain static.

While slip rings provide a secure connection, they eliminate wires, and yet they provide transmission of signal, power, and data. There are even slip ring types that can transmit and transfer other medium types, such as ethernet, fiber optic, coolant, water, gas or oil, and more.

They are very easy to install and they’re attached to the stationary part of a device while the rotation happens from the rotary part of a device that keeps the brushes rotating. As long as there’s rotation, slip rings provide a great purpose of electrical contact, power transmission, and more.

How are Slip Rings Made and How Many Types are There?

Two of the main components include a ring which is the outer part of the device and brushes or wipers that are placed on the inside of the ring.

The most common way a slip ring works is that brushes rotate upon the rotation from the rotary part of the device. They brush against the inner part of the ring, establishing a super secure and continuous contact as long as there is rotation.

There are 6 types and they include:

- Pancake ring

- Mercury contact ring

- Ethernet ring

- Fiber optic ring

- Through hole slip ring

- Miniature slip ring

However, keep in mind that each one of these types has its own version as well to ensure the versatile fit in almost any device or machine.

Companies such as Moflon have been providing the best slip rings in the industry for the last 30+ years and besides providing slip rings that fit the types above, they even produce custom slip ring solutions upon request from companies who need slip rings to fit into their projects.

Therefore, slip rings can really fit and benefit any type of device, any industry, and provide more than just the elimination of wire winding problems.

Where Can You Find Slip Rings?

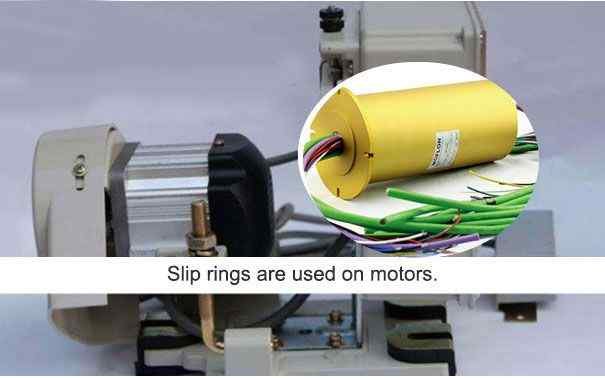

Slip rings are in so many devices we don’t even think of them on a daily basis. The best example of slip rings is medical imaging equipment.

You can find slip rings in equipment that uses rotary platforms with stationary bases such as CT or MRI scans.

However, slip rings are also used across so many industries so you can find them being used in aviation, aerospace, radar, robotics, factory automation, wind turbines, and many others.

Slip rings are even in the food and beverage industry, and can be found in marine dredging equipment, excavation solutions, wind turbines, and many others.

However, with so many slip rings on the rise thanks to the new technology such as the wireless power slip ring that comes with unlimited RPM, or a brushless slip ring that provides a super long lifespan – slip rings are being placed in so many more innovations, devices, and equipment.

Also, with custom slip ring solutions provided by companies such as Moflon, you can literally find slip rings in places you have never thought of before, so they’re really everywhere and are being used for so many different purposes.

Conclusion

With so many components and the whole and often difficult engineering process that involves so many factors, not many know about slip rings.

However, slip rings are good to know from an engineering point of view because they can help in so many different ways, even though they are built for one main purpose.

With so many additional benefits and advantages, it’s really incredible what a small device such as a slip ring is capable of and it really has a bright future in the world of modern engineering.