What are Brakes? Types of Braking Systems?

Brake is a device used to bring to rest a body which is in motion. It retards the motion by applying resistance. It is used for slowing, stopping and controlling a moving vehicle, axle, and wheel or to prevent its motion by friction. In braking operation the kinetic energy of the vehicle is converted into heat, which is dissipated to atmosphere.

Main function of Brake:

- To stop the vehicle safely.

- To control the speed of vehicle.

- To keep the vehicle in desired position.

Internal Expanding Brake:

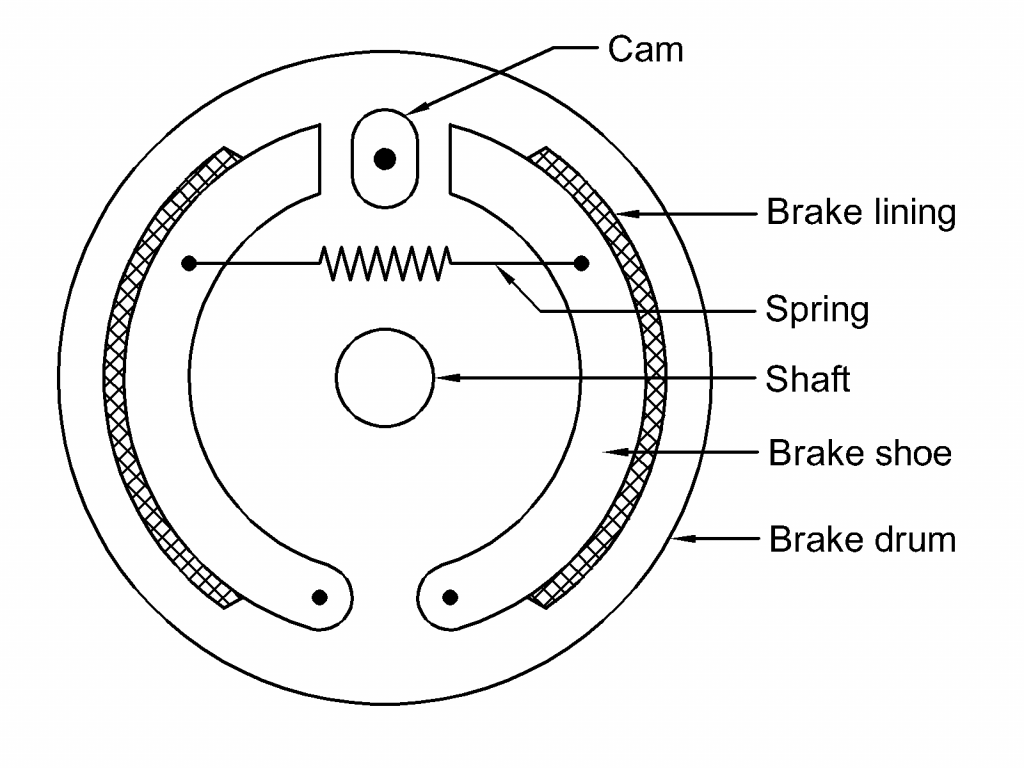

Internal expanding brakes are widely used in automobiles. It consists of two brake shoes which are lined with the friction material of high coefficient of friction and good wearing properties and it mounted inside the brake drum. Brake shoe is generally made of cast iron, aluminum or pressed steel. A cam is provided in between these shoes and it connected with the brake pedal through the mechanical leakage. The shoes having the frictional circuit that is liners. The spring is provided to return to its initial position after releasing the brakes. When brake pedal is pressed the cam rotates which pushes against the brake drum and brakes are applied.

Figure shows internal expanding shoe brake of mechanical system,

Hydraulic Brake:

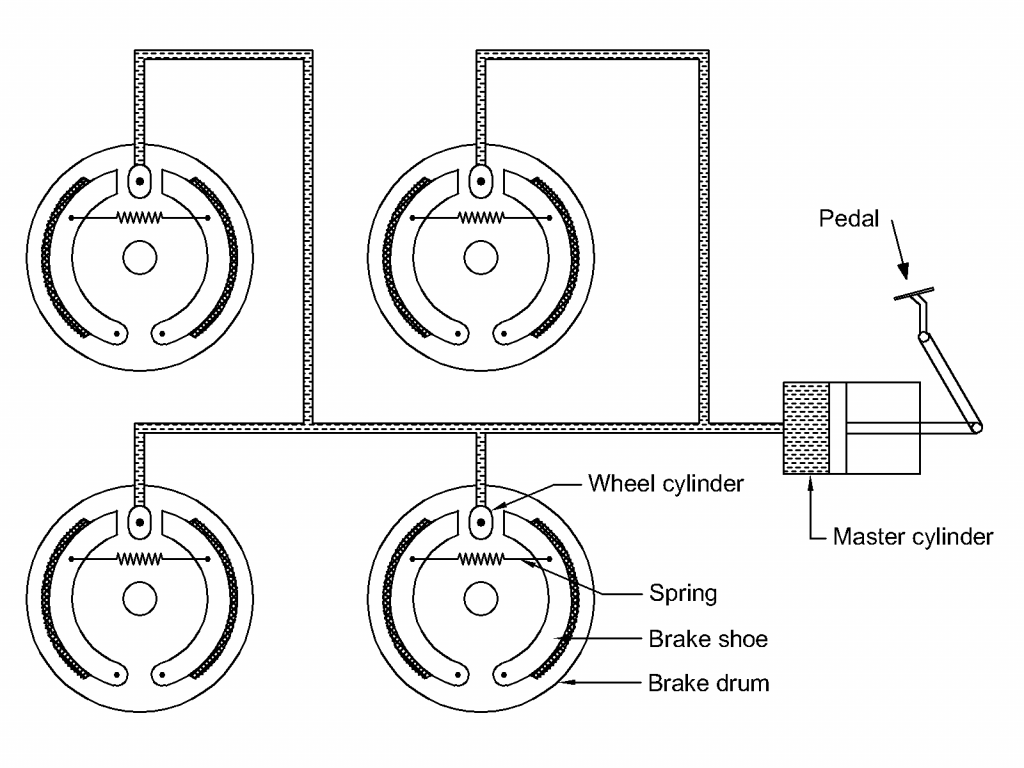

A hydraulic brake is a type of braking system which uses brake fluid. Force applied on brake pedal is transmitted to brake shoes for its actuation through a confined liquid known as brake fluid. The brake fluid is a mixture of Glycerin and Alcohol or Castor oil and some additives.

It consists of master cylinder which is connected by tubing to the wheel cylinders through the capillaries. The system is filled with brake fluid under light pressure when brakes are not in operation.

Each wheel cylinder has two pistons they are connected with the brake shoe. The pedal can operate with the master cylinder as shown in figure.

When brake pedal is pressed, the master cylinder piston is pushed inside and develops the pressure and the pressure is transmitted quickly to the wheel cylinder. And the wheel piston cylinder pressed the brake shoe. When driver releases the brake pedal, the master cylinder returns to its original position due to the return spring.

External Shoe Brake:

Simple shoe brake consists of a brake drum and a shoe or block mounted on the drum. The block attached to the lever. An arrangement of simple shoe brake is shown in figure,

The shoe is made up of softer material than the drum so that the block can be replaced easily on wearing. For light and slow vehicles, wood and rubber are used whereas for heavy and flat vehicles, cast steel is used.

When the force is applied on the lever the friction between drum and shoe increases and the brake is applied.

This type of brakes is widely used in railways, bicycles, etc.

Differential Band Brake:

The band brake consists of a rope, belt or a flexible steel band lined with a friction material which is mounted on the circumference of the brake drawn. The one end of the band is attached to the lever at the end and at a same distance from the fulcrum pin.

When the force is applied at the lever the band tights the drum and brakes are applied.

Tension ratio,

T1/T2 = eμΘ

Braking torque,

Tb = (T1 – T2) × r

Where,

T1 and T2 = Tension in belts.

r = Radius of belt drawn.

μ = Coefficient of friction.

Θ = Angle of lap.

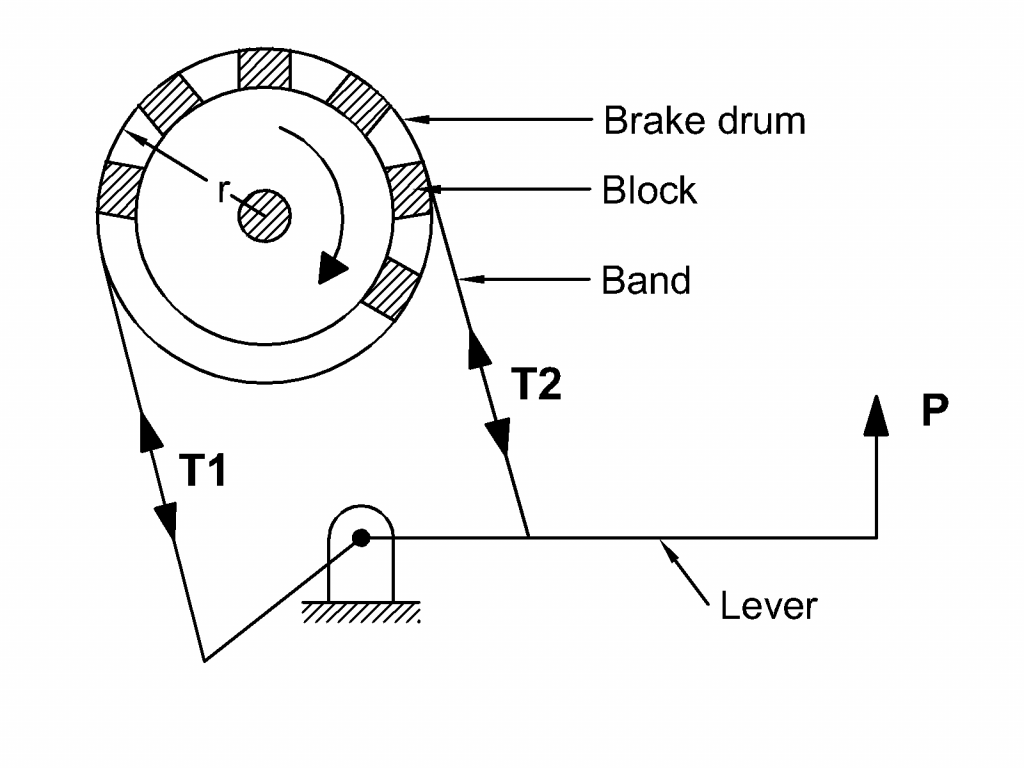

Band and Block Brake:

The band and block brake consists of a number of brake shoes fixed to the inside surface of the flexible steel band as shown in figure,

In band and block brake, the wooden blocks are mounted on the drum and then the steel bond is wounded around them. The friction between the blocks and the drum provides required braking torque.

Braking Torque,

Tb = (T1 – T2) × r

Where,

T1 and T2 = Tension in belts.

r = Radius of belt drawn.

μ = Coefficient of friction.

Θ = Angle of lap.

Concept of self-locking and self energizing of brakes:

In the shoe and band brakes, when the braking force is required (P), if it is zero or negative to apply the brakes, it is called as self locking brakes.

When the force of friction helps to apply the brakes, it is called as self energizing brakes.