Introduction to MasterCAM

MasterCAM is one of the most popular a software used in Computer-Aided Manufacturing (CAM). It is a suite of Computer-Aided Manufacturing (CAM) and CAD/CAM software applications developed by CNC Software, LLC. In the year of 1983 founded in Massachusetts by CNC Software.

In the world of Computer-Aided Engineering (CAM), the MasterCAM is a solution revered for its versatility and robust capabilities.

What is MasterCAM?

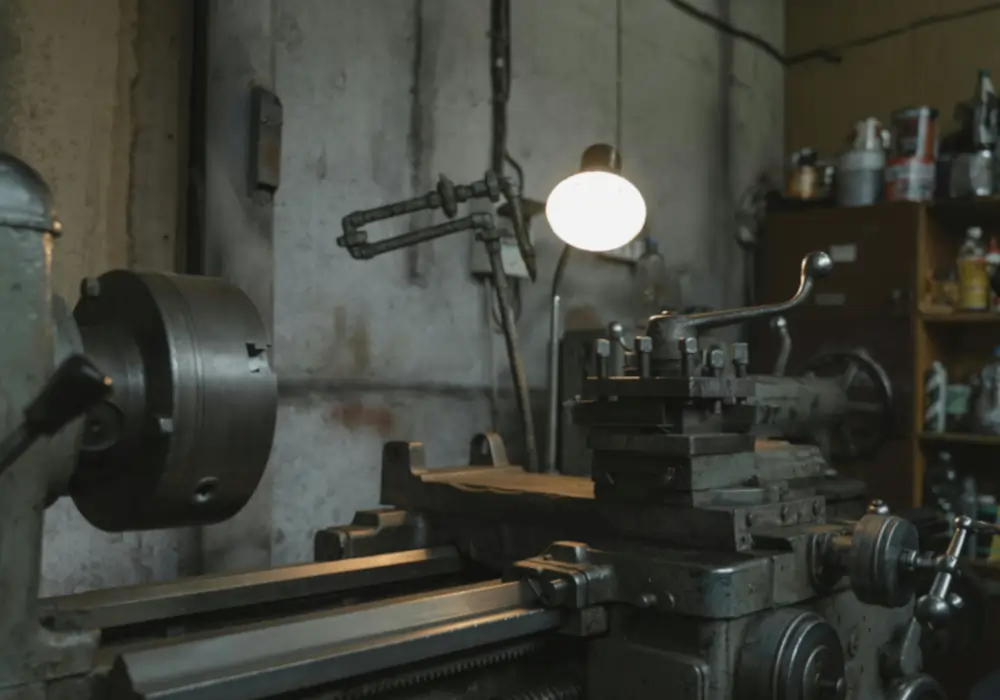

MasterCAM emerges as a powerhouse, which provides a collection set of tools for machining to engineers, designers, CNC operators and machinists for translating digital designs into intricately machined components. MasterCAM plays one of the most important roles in the field of machining. MasterCAM understands its features, applications, and the pivotal role it plays in shaping modern manufacturing processes.

Mastercam is a main product of CNC Software. The CNC Software are headquartered in Tolland, Connecticut. It started as a 2D CAM system with integrated CAD tools that let CNC operators and machinists to design virtual parts and components on a computer screen and also guided computer numerical controlled (CNC) machine tools in the manufacture of parts.

What is Computer-Aided Machining (CAM)?

Computer-Aided Machining (CAM) also known as Computer-Aided Manufacturing is the use of software to control machine tools in the manufacturing of work pieces. It is an automated method of machining a product by using computer generated code by using CAM software for machining with the help of 3D CAD design machine component.

Computer-Aided Machining (CAM) is a technology that uses computer software and hardware for planning, management, and control of manufacturing processes, to perform the machining operations.

Read Also: Best Mechanical Engineering Softwares

Advantages of MasterCAM:

Here are some of the advantages and benefits of MasterCAM are as follows,

- MasterCAM provides engineers, designers and machinists a wide range of advanced design tools, including 2D and 3D modeling to perform various machining operations.

- MasterCAM is capable to perform multi-axis machining and allows for the creation of complex parts with multiple complex curves and angles.

- MasterCAM offers intelligent toolpaths to build your tool assemblies and save them for future use to eliminate repetitive work and to reduce machining time and improve surface finish.

- MasterCAM also have an ability to generate and manipulate Computer-Aided Designing (CAD) 3D models.

- MasterCAM helps to configure your operation defaults for your specific needs.

Applications of MasterCAM:

MasterCAM is one of the popular software used in computer-aided manufacturing. It is widely used in various fields of engineering, industries and manufacturing. Here are some of the applications of MasterCAM are as follows,

- Precision in Manufacturing: MasterCAM is popularly used for industries where precision is the requirement for manufacturing of component. From the industries such as aerospace parts to medical components, MasterCAM is widely sued.

- Die and Mold Making: For making of molds and die, engineers need seamless machining experience. MasterCAM is capable for machining seamless shine molds and dies for injection molding or dies for stamping.

- CNC Machining: MasterCAM is widely used in CNC machining where machinist and engineers need a software to perform precise and seamless machining operation.

- Multi-Axis Machining: MasterCAM supports multi-axis machining operations to allows the production of complex parts that require simultaneous movement of the cutting tool along multiple axes.

- Education and Training: MasterCAM is widely used in educational institutions and training centers to serve a knowledge and training of MasterCAM and operations of computer-aided machining to students, engineers and machining professionals.

MasterCAM stands at the forefront of driving innovation in precision manufacturing. It is widely used across various industries that shaping the future of machining and manufacturing with precision and efficiency that make machining better.