Angular measurement can be defined as the measurement of an angle formed by the two rays at a common vertex. Angles are measured in degrees using protectors.

For angular measurement, there are various devices are available based on the type of component to be measured and the accuracy and precision to be required during measurement.

Following are the different angular measuring instruments are as follows,

- Vernier Bevel Protector.

- Optical Bevel Protector.

- Universal Bevel Protector.

- Sine Bar.

- Angle Gauges.

- Clinometer.

Vernier Bevel Protector:

The bevel protectors are the basic and widely used as the angular measuring device. Vernier Bevel Protector is the simplest angular measuring device which has vernier scale like a vernier caliper with an acute angle for measurement.

Sine Bar:

Sine bar is the simple instrument for angular measurement to utilize the high degree of accuracy. It is used with slip gauges for accurate angle measurements.

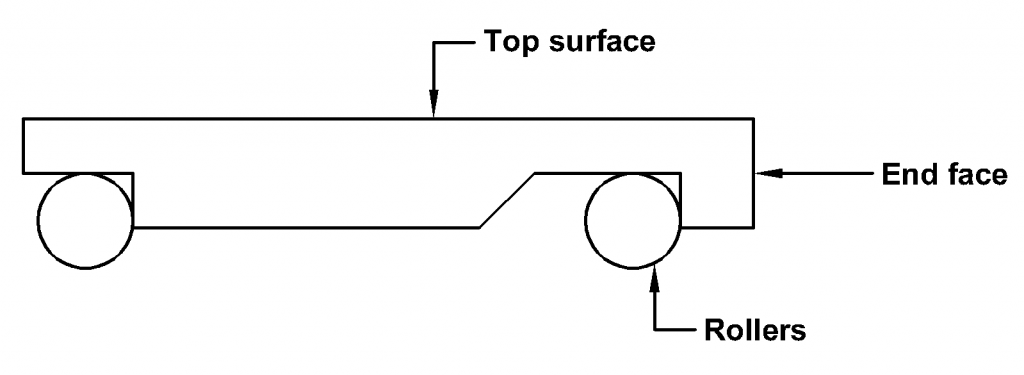

It consists of a steel bar and two rollers which are made up of high carbon steel with high chromium corrosion resistance. The rollers are accurate and in equal diameters and attached to the bar also to the upper surface of the bar. The nominal distance between axes is 100mm, 200mm or 300mm which is specified the distance between two rollers. When the rollers are comes in contact with a flat surface, the top of the bar is parallel to the surface.

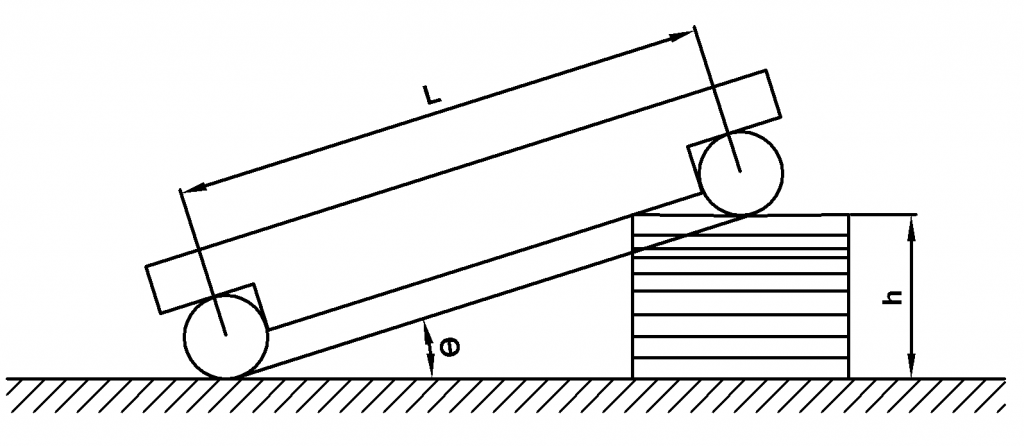

The working principle of sine bar is based on the laws of geometry and trigonometry. For measurement of an angle, one roller is placed on the surface and second roller is place on the combination of slip gauges.

If ‘h’ is the height of the combination of slip gauges to be used for second roller and ‘L’ is the distance between the centers of two rollers.

The angle to be measured is determined by indirect method as a function of sine. So, the device is called as sine bar. It is used for checking of lathe angle and other angle measurements.

Clinometer:

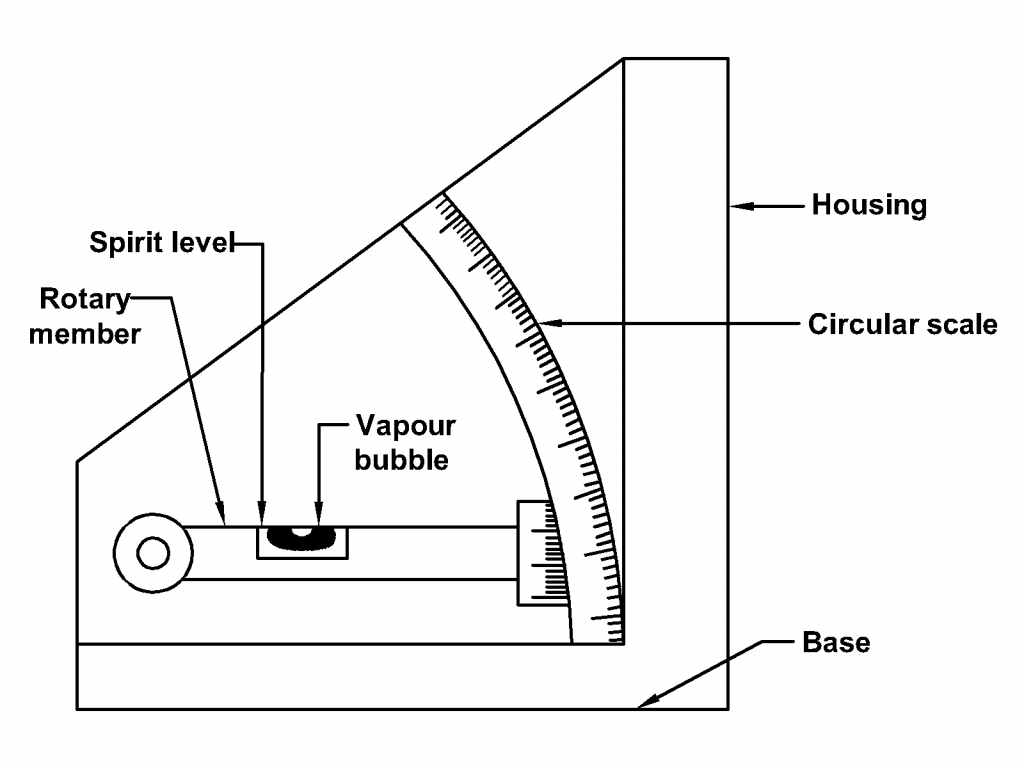

A clinometers is a special type of angular measuring device of the application of spirit level.

The spirit level is mounted on a rotary member carried on the housing. The one face of housing forms the base of the instrument and a circular scale is mounted on it. The angle of inclination can be measured by the circular scale. The Clinometer is used to determine the included angle of two adjacent faces of a work piece. The instrument base is placed on one of the surfaces and the rotary member is adjusted till zero reading of the bubble is obtained. A second reading is taken by keeping the instrument on the other surface. The included angle between the faces is then the difference between the two readings.

The Clinometer is used for measuring large angles between inclined surfaces and checking angular faces and relief angles on large cutting tools.