Lathe Machine | Definition, Working Principle, Construction Details and Applications

Lathe machines have been used in workshops for centuries, used to perform various operations for shaping and cutting materials with precision.

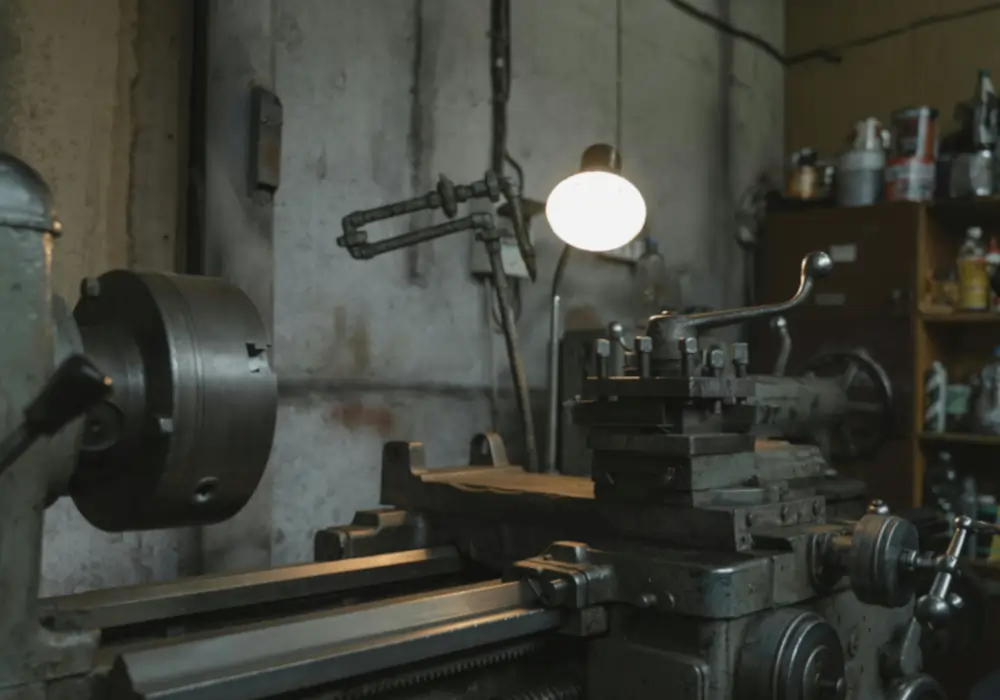

The lathe machine is a fundamental tool in machining, known for its ability to shape and cut materials with precision. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various machining operations such as turning, cutting, knurling, drilling, facing and threading. Hence, the lathe is also referred to as the “Mother of all machines.”

Working Principle of Lathe Machine:

The working principle of a lathe machine is based on the rotation of the workpiece and a stationary cutting tool. The workpiece is securely hold on chuck mounted on a headstock which also get support from tailstock. The cutting tool is rigidly mounted on the tool post which is used to perform a machining operation on the revolving workpiece.

Let’s explore the construction details, fundamental parts and operations of a lathe machine and understanding of each component and its function in details.

Read Also: Machines in Mechanical Engineering for Production Process

Construction Details of Lathe Machine:

The construction details of a lathe machine is designed to provide the strength, rigidity, accuracy, precision, and durability to perform various machining machine operations. Here is the complete construction details of lathe machine as follows,

Legs:

The legs of a lathe machine are the supports that elevate and stabilize the entire lathe machine structure. The legs are made from cast iron or steel, these legs are designed to bear the weight of the lathe machine.

Tray:

The tray on a lathe machine is a flat surface located on the lathe bed. The main function of lathe machine is to collect metal chips and burrs generated while performing machining operations. The tray helps keep the work area clean.

Bed:

The bed is the base of the lathe machine. The bed is serve as the foundation of lathe machine upon all the machine components are installed. It is made from cast iron or steel to provide stability and minimize vibrations during operation. The bed is supported by large box-section columns and is made of cast iron or a nickel cast iron alloy. The bed is mounted on the legs.

Feed Mechanism:

The feed mechanism controls the movement of the carriage and cross-slide, allowing for precise control over the cutting process. The feed mechanism can be operated manually or automatically by the operator to provide consistent and accurate cuts and surface finish of the workpiece.

Leadscrew:

The leadscrew is a long-threaded shaft that runs parallel to the bed. It is used as a linkage in a machine to convert turning motion into linear motion. The leadscrew mainly used for threading operations and to drive the carriage during automatic feeding. The feed rod is used for general feeding operations, offering smoother control.

Headstock:

The headstock is the powerhouse of the lathe machine. The headstock containing the main spindle, speed change mechanisms, gear trains and pulleys that control speed. The headstock is located on the left side of the lathe bed. The working of headstock is to transmit electricity to the components and also houses the spindle.

Spindle:

The spindle on a lathe machine is an important component used for holding and rotating the workpiece during machining operations. Spindle is located in the headstock powered by the machine’s motor and can rotate at various speeds, depending on the machining requirements.

Chuck:

The chuck is attached to the spindle and holds the workpiece securely. Chucks are specialized clamps made to hold the objects having radial symmetry such as cylinders having jaws to secure the workpiece. There are various types of chucks, including three-jaw, four-jaw, and collet chucks.

Tailstock:

The tailstock is located on the right side of the bed. The tailstock is mounted opposite to the headstock and can slide along the bed and be locked in place. The tailstock provides additional support for long workpieces and holds tools for operations like drilling, reaming, tapping, etc. It includes the dead center, adjustment screws, and handwheel.

Hand Wheel:

The hand wheel on a lathe machine is a manually operated wheel which is used to control the movement of various components, such as the carriage, cross-slide, or tailstock. The hand wheel is used to adjust the position of the cutting tool and the workpiece.

Gear Box:

The gearbox in a lathe machine is one of the important part responsible for controlling the spindle speed and feed rate. It is used to allows the operator to adjust the speed of the spindle. The gearbox contains a series gears, which are used to vary the speed of the spindle.

Workpiece:

The workpiece is the material being machined or shaped during an operation. The workpiece can be made of various materials including metals, wood or other. The workpiece is securely mounted on the spindle, using a chuck and rotates and the cutting tools is used to perform various machining operations.

Carriage:

The carriage holds and moves the cutting tool along the length of the workpiece. The carriage assembly consists of the saddle, cross-slide, compound rest, and tool post. The carriage is constructed from cast iron for durability and precision. It is mounted in the area between the tailstock and headstock. The tool post is mounted and can move in the longitudinal direction on the bed. It consists of a cross slide, a compound rest, a feed table, and a tool post.

Saddle:

Saddle is a cast in the shape of an H and installed on top of the lathe machine. It is used to supports the cross-slide, the compound rest, and the tool post.

Apron:

The apron is attached to the front of the carriage and contains the controls for the feed mechanisms and the threading operations. The apron controls the carriage’s movement and houses the mechanisms for automatic feed and threading.

Compound Rest:

The compound rest is a component mounted on the carriage, allowing the cutting tool to be adjusted at precise angles.

Tool Post:

The tool post is mounted on the carriage and holds the cutting tool. The tool post can securely hold the cutting tool in place. It can be adjusted to various angles and positions tom perform different cutting operations. The tool post is mounted on the compound rest and used to carry cutting tool holders.

Oil Sump:

The oil sump in a lathe machine is used as a reservoir mounted at the base of the lathe machine, designed to hold and circulate lubricating oil throughout the machine and moving parts.

Applications of Lathe Machine:

The lathe machine is used since centuries in workshops, production houses, industries and everywhere to perform various machining operations. Lathe machines is a useful machine used in various industries for a wide range of applications. Here are some of the main applications of lathe machine are as follows,

- The main application of lathe is to create cylindrical parts by performing turning operation.

- Lathe machines are used to cut internal and external threads on cylindrical parts, such as nuts, bolts and screws.

- Lathe machines are used to make wooden objects such as decorative pots, baseball bats, ornate table legs, wooden bowl, and platters.

- Lathe machines are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass working.