What is Drilling? Definition, Main Parts, Factors Selection, Operations

Drilling is a process of producing a cylindrical hole using drill bit, in a solid material. It is a process in which a drill bit is uses to cut a hole of a circular cross-section in a solid material. The drilling is a single purpose machine for the production of holes. Drilling process is the best method of producing holes. The drill bit is rotary cutting tool, a cylindrical bar with helical flutes and radial cutting edges at one end.

Drilling operation simply consists of rotating the drill and feeding it into the workpiece being drilled. The process is simple and reasonably accurate and drill is easily controlled both in cutting speed and feed rate. The is probably one of the original machining processes and it is one of the most widely machining process.

What is Drill?

Drill can be defined as a rotary end cutting tool which having one or more cutting lips and having one or more helical flutes for passage of chips and admission of a cutting fluid.

Drills are commonly used in metal working, construction, fabrication work, wood working, etc. The high-speed steel drills are most commonly used drill bit.

The flutes are providing on a twist drills to provide cutting lips and to allow cutting fluid to reach the cutting lips.

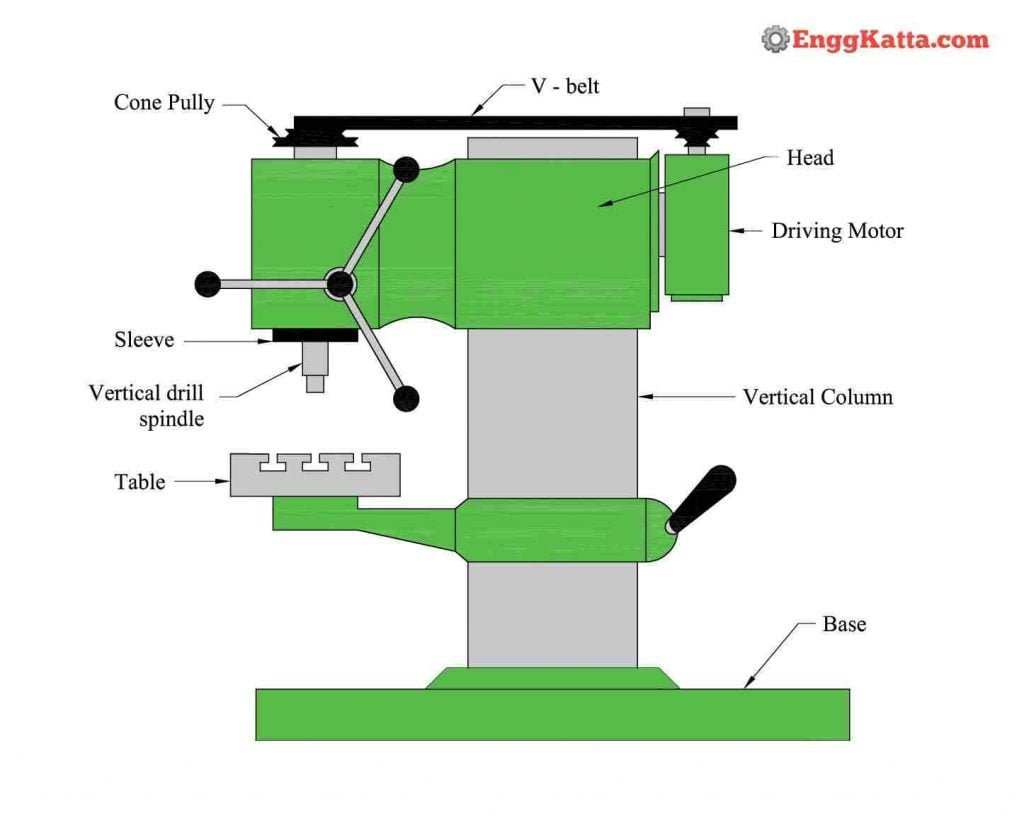

Main Parts of Drilling Machine:

The drilling machine is a single purpose for the production of holes. Drilling is generally the best method of producing holes. The main element of drilling machine as shown in figure below,

Base: It is a solid foundation o which the column or pillar is mounted.

Column: It provide the solid support for the worktable.

Worktable: It provide the horizontal surface with the alignment connected with drill spindle and hand wheel.

Motor: The motor helps the spindle to rotate the pulley and gearbox.

Hand Wheel: It provide the feed to the drill with rack and pinion mechanism.

Spindle: It provide the holding and locating the cutting tool.

Factors for Selection of Drilling Machine:

Some of the factors considered while selection of a drilling machine are as follows,

- The material being drilled in a drilling machine.

- The size of a hole.

- Speed and Feed required during operation on drilling machine.

- Need for coolant while working.

- The capacity of a drilling machine.

- The quality of a hole.

- Method of workpiece holding and clamping on work table.

- Orientation of a drill.

Read Also: Machines in Mechanical Engineering for Production Process

Drilling Machine Operations:

There are mainly various operations that can be performed in a drilling machine. The operations performed on a drilling machine are,

Drilling: Drilling is an operation of predicting cylindrical hole by removing metal by rotating cutting edge of drill is known as drilling. Drilling is one of the simplest operations on a drilling machine.

Reaming: Reaming is an operation of finishing a previously drilled hole for greater accuracy using a drill. The tool used for reaming operation is known as reamer.

Boring: The boring operation is used to perform to make a hole enlarge a previously drilled hole.

Counter Boring: The counter boring is an operation of enlarging the end of a hole cylindrically like a bolt head, is known as counter boring.

Counter Sinking: The counter sinking is an operation of enlarging the hole cone-shaped at the end of hole, is known as counter sinking.

Tapping: The operation of forming an internal thread in a previously drilled hole, is known as tapping.

Trepanning: The operation of producing larger holes around diameter of over 50 mm, by removing metal along the circumference, is known as trepanning.

Spot Facing: The operation o smoothing and squaring the surface around a hole, is known as spot facing.